ROMDAS LCMS System Outputs: Patching and Rumble Strip

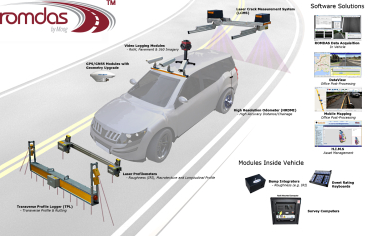

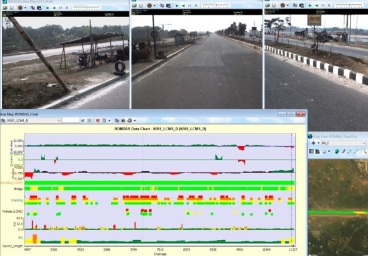

ROMDAS LCMS module now outputs Patch detection from the ROMDAS system automatically. Here we explain what the defects requirements are and how ROMDAS LCMS system can help achieve the results.

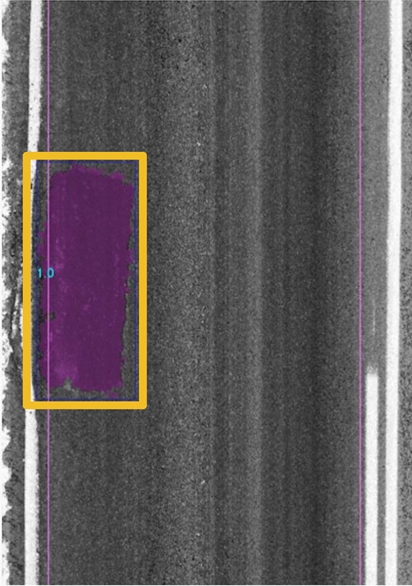

LCMS-2 Patching Detection

Patches are a common maintenance treatment that are found on various types of pavement surfaces. It is often put in place following underground utility work (a utility cut patch) or to fill a pothole. Generally, the Patch's location and dimension are required when assessing it's condition.

With ROMDAS Patching output, you receive the location, area, bounding box and FHWA defined severity rating for each patch.

If you would like to include the Patching output to your ROMDAS LCMS system, please connect with our Sales team and they can provide more information.

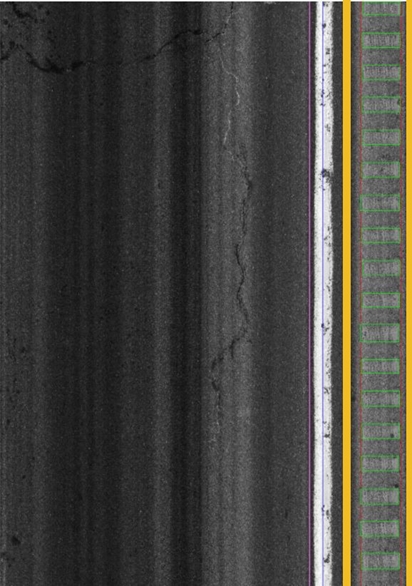

LCMS-2 Rumble Strip Detection

Rumble Stripes are an important safety feature to help alert drivers of the intended traffic path, or slow down the traffic. However, Rumble Stripes can create issues when using 3D Profiling systems like LCMS, potentially resulting in false positives for crack detection.

ROMDAS LCMS-2 system with Rumble Stripe module detects the presence of both raised and milled Rumble Stripes. The detected Rumble Stripes can be automatically excluded before crack detection phase and this improves the crack reporting accuracy. You will receive the Rumble Stripe type, location, bounding box and average depth.

Contact us today if you would like to include Patching and Rumble Stripe detection in your ROMDAS LCMS System.