A high resolution sophisticated NSV commissioned in Qatar

The year has started off on an exciting note with many planned installations and trainings

Location: Doha, Qatar

The year has started off on an exciting note with many planned installations and trainings. In that spirit, it has been an exciting opportunity for the entire ROMDAS team to work with the Public Works Department of Qatar (Ashgal). The Ashgal officials required us to assist them to configure a ROMDAS system that can meet their unique road system and requirements.

As we started our discussions with the officials, we quickly understood that they were unsure about the “fit-for-purpose” system needed to conduct surveys for maintenance as Qatar gets ready to host the 2022 Football World Cup series. In preparation of this, Qatar is undertaking major road developments, with new survey methodologies and data collection capabilities playing a big role. For this, the Ashghal officials were looking for a close partner who can provide the latest technology, input on survey techniques and customise data processing to ensure that data is compatible with their existing Pavement Management System (PMS).

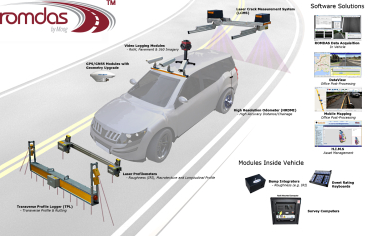

ROMDAS’ Sales and Supply manager, Ben, took time to discuss the details with the government officials. Ben presented an overview of the full range of ROMDAS and its output capabilities, impressing the officials. ROMDAS was then able to narrow down the design for a sophisticated network road survey system. After gaining an understanding of the ROMDAS system, the officials decided to commission two (2) separate systems through their local contractor, Seashore Engineering and Contracting. One system was a high-resolution and state-of-the-art LCMS system and the other was a basic Laser Profilometer system to collect roughness (IRI) data.

ROMDAS team worked closely with the government officials and their contractor for a smooth execution process. The officials also visited the ROMDAS factory in New Zealand to assess the system progress and quality as part of their process.

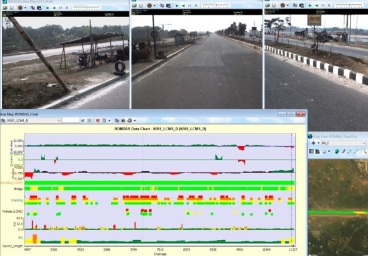

The first system includes the new LCMS2 along with the upgrades for Roughness and Geometry, the 360-degree camera module along with DataView and Mobile Mapping software. This system also included the ROMDAS Geometry Unit along with several other and extended services. All the data was geo-referenced with GPS coordinates and distance.

As ROMDAS has been on spree of breaking its own records, the installation of this system was done within 4 days! So far, this is one of the fastest install for ROMDAS and one of its best for a similar LCMS system.

The second system was a basic Laser Profilometer system with GPS, roughness data collection being the primary output. The installation was undertaken by Ben, Paul and Harrison with the training conducted onsite by Paul and Ben.

ROMDAS is the first network survey system on Qatar roads. One of the interesting aspects of this project was that the system processes had to be customised to work with Qatar’s unique road system. The Qatar team uses several GIS databases for their network. In the past they had used Lidar but they now wanted to record roadside assets specifically to assess the type of assets, their numbers and location, and their current condition. For this, we recommended our 360-degree camera package with Mobile Mapping Software which recorded visual information directly from survey videos that were referenced to GPS coordinates. This offered them acceptable GPS accuracy with much required flexibility, reducing their processing time and costs compared to the Lidar system.

We thank the Ashgal Department officials and the team from Seashore Group for their patience and cooperation for local organisation to make it easier for our technician. We are pleased to have contributed in the Department’s survey process and are now riding confidently on Qatar roads.

Enquire about a ROMDAS System today